The railroad industry has long served as the backbone of America’s transportation infrastructure, but it’s time for a transformation on the track.

Evertrak is leading this charge with its mission to innovate and disrupt the status quo. By reimagining the humble railroad tie, Evertrak is setting new standards for performance, sustainability, and cost-effectiveness in rail infrastructure.

In this blog, we’ll outline the current state of railroad tie infrastructure sparking the catalyst for change and highlight five compelling reasons why Evertrak’s railroad ties are laying down the tracks that are paving the way for the future of railroads.

The Current State of Railroad Ties

For nearly two centuries, wood has been the material of choice for railroad ties. Wood makes up the vast majority of railroad ties, accounting for around 93% of all ties. While wood ties have served railroad companies well, such ties come with significant challenges: decay, environmental concerns, and high maintenance requirements have plagued railroad companies for decades.

There are approximately 3,000 railroad ties per mile and today, the industry installs an estimated 23 million wood ties each year. This high demand for wooden railroad ties contributes to deforestation and creates a cycle of costly, frequent replacements.

Evertrak Ties and Innovation: The Evertrak 7000

Enter the Evertrak 7000, a reinforced composite rail tie that’s changing industry standards. Made from exceptionally durable Glass Fiber Reinforced Polymer (GFRP) using recycled plastic, this innovative tie has the advantage of combining strength, durability, and sustainability in a single package, meeting and exceeding the performance of traditional wood railroad ties.

Transforming Tracks: 5 Reasons Railroads Are Switching to Evertrak Ties

Each year, freight trains move 1.6 billion tons of goods across 140,000 miles in North America. In order to maintain and expand service along these rail lines, alternate materials used to replace wood ties must be strong, easy to integrate into existing infrastructure, and deliver long-lasting value.

Evertrak checks each of these requirements, creating a new type of railroad tie made from recycled plastic that’s designed to enhance railroad tracks and drive the industry forward. Here’s what railroads are realizing they can expect from Evertrak’s railroad ties:

1. Superior Durability and Longevity

Made from composite materials, Evertrak’s railroad ties are built to last. While traditional wood ties typically need to be replaced every 8 to 15 years in high-rot zones, Evertrak’s composite railroad ties are designed to perform reliably for up to 50 years under the same conditions, wear and tear, and environment. Evertrak’s railroad ties achieve such exceptional longevity due to their resistance to decay, insects, and harsh environmental factors that typically degrade wooden railroad ties.

2. Environmental Sustainability

Sustainability is at the core of Evertrak’s mission. By using recycled materials in their production, Evertrak’s railroad ties divert 180 million pounds of plastic for every 1 million ties produced annually.

Each Evertrak railroad tie produced also means fewer trees are cut down, contributing significantly to reducing deforestation. In fact, Evertrak’s efforts prevent the deforestation of 250,000 mature trees each year. Additionally, Evertrak’s railroad ties eliminate the need for harmful preservatives like creosote, a known carcinogen often used in wood rail ties.

3. Ties with Improved Performance

Once installed, Evertrak’s railroad ties don’t just match the performance of wood railroad ties—they exceed it. With strength and stiffness equivalent to wood, these ties have proven their worth and quality in rigorous testing. They perform consistently across a wide variety of environmental conditions, from extreme heat to sub-zero temperatures. In fact, validated fatigue models and in-track performance reveal Evertrak’s railroad ties perform at 3x the AREMA standard for composite ties.

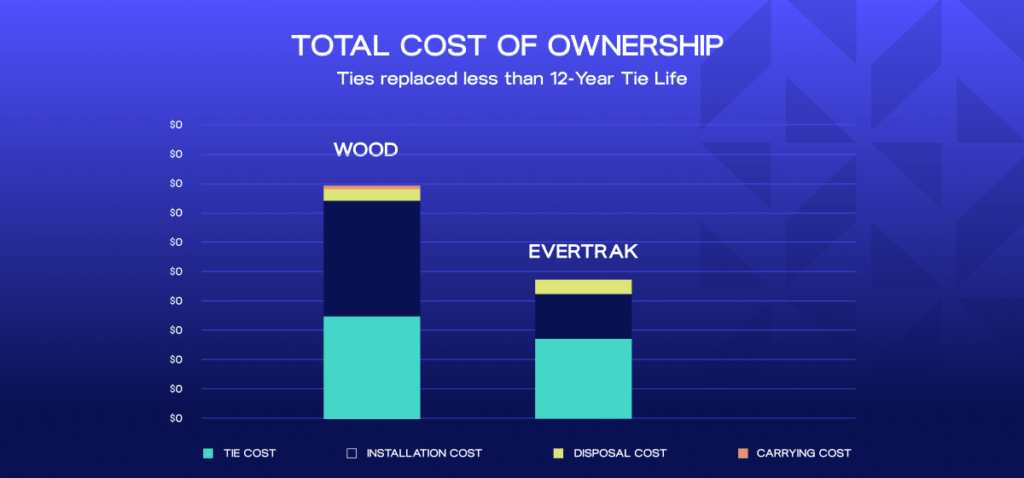

4. Value and Cost-Effectiveness

Total Cost of Ownership (TCOO) is the name of the game. Yes, annual budgets matter, but with long-lived assets like locomotives and steel, railroad companies can look beyond the annual budget horizon to TCOO. In fact, the extended lifespan of Evertrak’s railroad ties translates to significantly lower TCOO over time. Railroads can expect reduced maintenance frequency and lower replacement costs, leading to substantial savings in labor and materials over the decades-long lifespan of Evertrak’s railroad ties.

On the balance sheet, wood railroad ties are an asset with straight-line depreciation over 30 years. After 8-12 years, railroads classify wooden railroad ties as impaired assets when they take them out of service for replacement. And don’t forget: railroads pay to dispose of wood rail ties, typically costing $10/tie—and that cost is rising. These factors contribute to making Evertrak’s railroad ties less expensive over time and a valuable investment asset.

5. Versatility and Ease of Implementation

Evertrak designs its high-quality railroad ties to be fully interoperable with wood railroad ties, allowing for easy integration into existing infrastructure. They’re ideal for high-rot areas and extreme weather, with easy installation during regular tie renewal projects.

On Track: The Future of Rail Infrastructure with Evertrak Ties

The potential impact of Evertrak’s composite ties on the railroad industry is significant. At scale, Evertrak impressively saves millions of trees and repurposes tons of plastic waste. This shift toward sustainable practices can significantly improve public perception of the railroad industry and pave the way for future change.

Evertrak remains committed to continue its mission of true innovation and improvement. Through ongoing collaboration with industry partners and stakeholders, we’re not just creating a product but solving a problem, and we’re fostering a new era of rail infrastructure.The future of rail infrastructure is here, and it’s built on Evertrak railroad ties. Are you an industry professional looking to join this rail revolution? Read our FAQs to learn more about Evertrak’s solutions and reach out to speak with one of our experts.