With nearly 140,000 miles of track crisscrossing the country, railroads form the backbone of our nation’s transportation system.

For nearly two centuries, this vast network has relied on a seemingly simple component: the wood railroad tie. Now, the industry faces new challenges. The world has run out of old growth trees, and we live in an era of heightened environmental responsibility and shifting resource availability. It’s time to re-examine the true cost of wood railroad ties.

The Lifecycle of Wood Ties: A Costly Proposition

At first glance, wood ties may appear to be the most economical option. However, a closer look at their lifecycle reveals a different story.

While the numbers vary, the installed base of wood railroad ties in North America is around 570 million. The entire installed base was replaced in the last 26 years, according to the Railway Tie Association. The RTA also says that wood ties have a 33–42 year lifespan and about 20 million ties are replaced every year, about 3.5% of the installed base.

If the average lifespan is 33–42 years, how could the entire installed base have been replaced in 26 years?

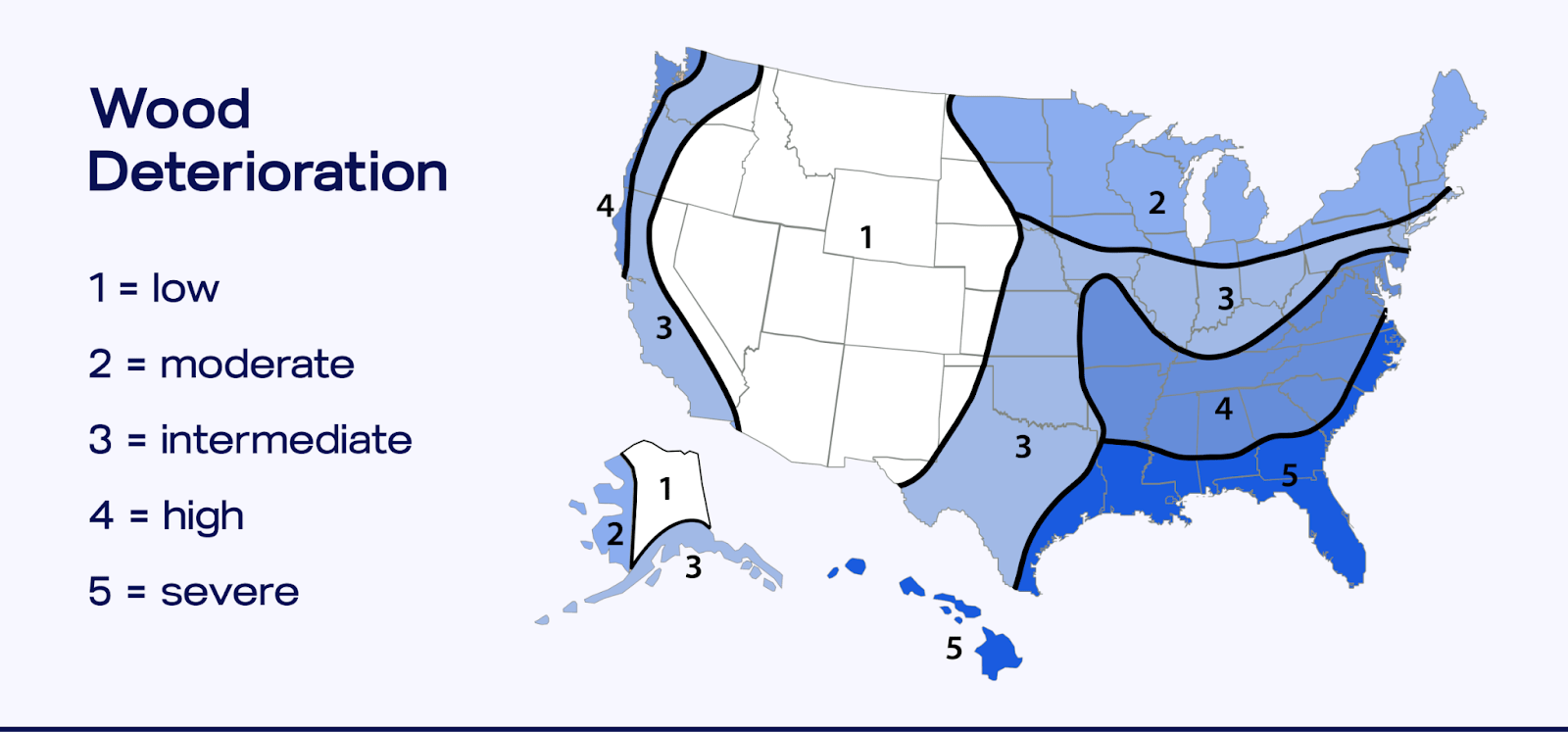

The answer is that 4-6 million ties per year are being replaced every 8–12 years. In the high-decay zones, 10–12% of the installed base is replaced every year. Maintenance practices have evolved to replace millions of ties every 8–12 years, including aging ties that will be replaced in less than decade.

These maintenance practices are not sustainable, not only by measures of the balance sheet and income statement but also the environmental impact.

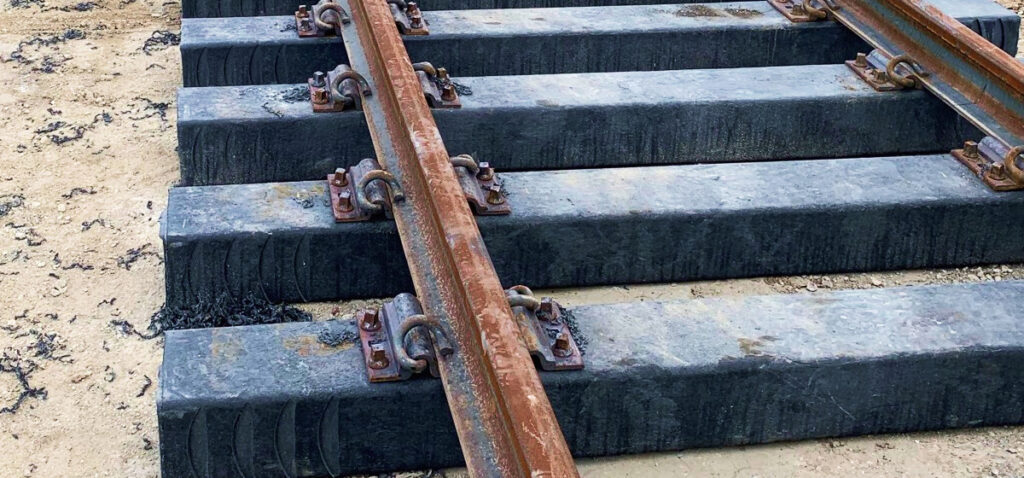

Evertrak 7000 ties, made from recycled plastic and engineered for durability, boast a lifespan of up to 50 years, even in challenging environments. This longevity translates to fewer replacements, lower maintenance costs, and reduced disruptions to rail operations over the long term. Simply put, Evertrak delivers advantaged Total Cost of Ownership. Also, Evertrak’s ties are recyclable at end of life, meaning that the tie is an asset that has economic value and is not a liability.

The Environmental Toll: Deforestation and Chemical Contaminants

Beyond the direct financial costs, the use of wood railroad ties carries a heavy environmental price tag.

Wood ties account for 90–93% of railroad ties used. Each year, approximately 6 million mature trees are cut down to supply the 22 million wood ties required to meet current demands. This ongoing deforestation not only diminishes valuable forest ecosystems but also reduces the carbon sequestration capacity of these natural resources.

Toxic Treatment

Furthermore, the vast majority of wood ties are treated with creosote, a toxic preservative known to leach into soil and water over time. This chemical contamination poses risks to both the environment and human health, with potential liabilities for railroad companies.

Evertrak 7000 ties offer a sustainable alternative, diverting plastic waste from landfills and eliminating the need for harmful chemical treatments. At 1 million ties per year, Evertrak would sequester 180 million pounds of plastic annually while also preventing the logging of 250,000 mature trees.

The Cost of Time: A Dwindling Resource

As the railroad industry looks to the future, the cost of time becomes an increasingly critical factor.

The availability of mature hardwood trees suitable for railroad ties is diminishing rapidly. The once-abundant old-growth forests that supplied high-quality timber are largely depleted, leaving younger, less-dense trees that lack the same durability.

Moreover, as public awareness of the health and environmental risks associated with creosote grows, tighter restrictions on its use are likely to follow. This regulatory shift could further complicate the already challenging task of sourcing, maintaining, and disposing of wood ties.

By investing in composite tie technology like the Evertrak 7000, railroads can insulate themselves from these time-sensitive pressures. Our ties offer consistent performance and reliability, regardless of the changing landscape of timber resources and chemical regulations.

The Evertrak 7000 Advantage: Reimagining Railroad Infrastructure

At Evertrak, we understand the multifaceted costs that railroads face in maintaining their infrastructure. That’s why we’ve developed the Evertrak 7000 tie—a solution that addresses the financial, environmental, and long-term challenges associated with traditional wood ties.

Our Glass Fiber Reinforced Polymer (GFRP) ties, made from recycled plastic, offer strength and durability that rival the best hardwood ties. Because Evertrak 7000 ties last five times longer than wood ties, they require significantly fewer replacements over time. This reduces the amount spent on labor, materials, disposal, and the costs associated with track downtime during maintenance.

Embracing Change

The benefits of Evertrak’s ties extend far beyond the bottom line.

By eliminating the need for creosote and reducing the demand for hardwood timber, Evertrak 7000 ties represent a major step forward in the railroad industry’s sustainability efforts. Our manufacturing process diverts plastic waste from landfills, contributing to a circular economy and reducing the industry’s environmental footprint.

Expected to reach a value of $1.4 billion by 2031, the North American railroad tie market takes up a large portion of the industry’s annual maintenance budget. As railroads face mounting pressure to operate efficiently, sustainably, and safely, the choice of infrastructure materials has never been more important. The true price of wood ties—financial, environmental, and temporal—is simply too high to ignore.

With Evertrak 7000, we offer a solution that not only addresses these costs but also positions railroads to lead transportation efforts in adopting a more resilient and responsible future.

The Future of Rail: Innovation and Sustainability in Tandem

For the railroad industry, decisions made about infrastructure today will shape the future of transportation for generations to come.

By embracing innovative solutions like Evertrak 7000 composite ties, we have the opportunity to create a rail system that is not only more efficient and cost-effective but also more sustainable and environmentally responsible.

At Evertrak, we proudly lead this charge.

Our composite ties represent the culmination of years of research, engineering, and a deep understanding of the needs of the modern railroad industry. We’re proud to partner with forward-thinking railroads, like Union Pacific, that recognize the value of investing in long-term, sustainable infrastructure solutions.

As we move forward, it’s clear that the price of progress cannot be measured in dollars alone. The true cost of our choices must account for the environmental impact, the health and safety of our communities, and the long-term viability of our rail networks. By choosing Evertrak 7000 ties, railroad decision-makers are not only saving money but also demonstrating their commitment to a more sustainable and responsible future.

It’s time to rethink the price we’re willing to pay for our railroad infrastructure. The costs of traditional wood ties—hidden in plain sight for so long—are simply too high. With Evertrak 7000, we have the power to chart a new course, one that leads to a stronger, more resilient, and more sustainable rail system for generations to come.