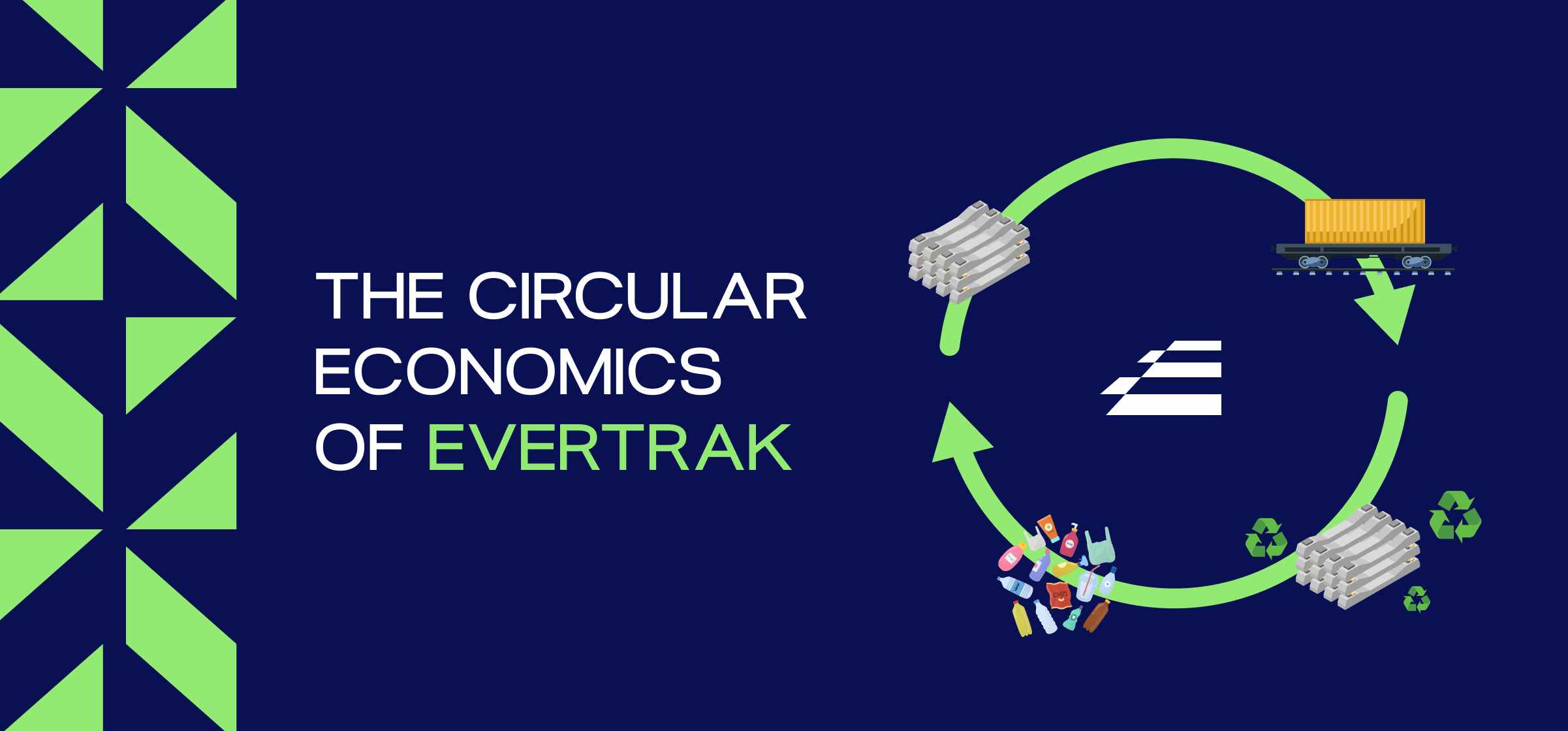

Circular economics represents the foundation of sustainable manufacturing—where end-of-life products become raw materials for new goods rather than waste.

This is key in industries working with plastic while trying to be sustainable. In fact, the benefits of recycling plastic are undeniable: reduced fossil fuel consumption, decreased greenhouse gas emissions, and significantly less plastic pollution contaminating our landscapes, waterways, and oceans.

Yet circular plastic economics cannot gain momentum without a compelling economic engine driving the recycling process.

For true sustainability, recycling must align with economic self-interest at every level of the supply chain.

Consumers need motivation to hold onto an empty bottle until they find a recycling bin. Similarly, manufacturers require tangible value from maintaining separate waste streams for recyclable materials. Without economics driving these decisions, recycling remains an admirable but insufficient practice limited to those already committed to environmental causes.

The circular economy demands real financial incentives. Manufacturing exists because economics drive entities to convert materials into finished goods others will purchase. Recycling needs this same economic imperative to thrive at scale.

Evertrak: Powering the Circular Economy

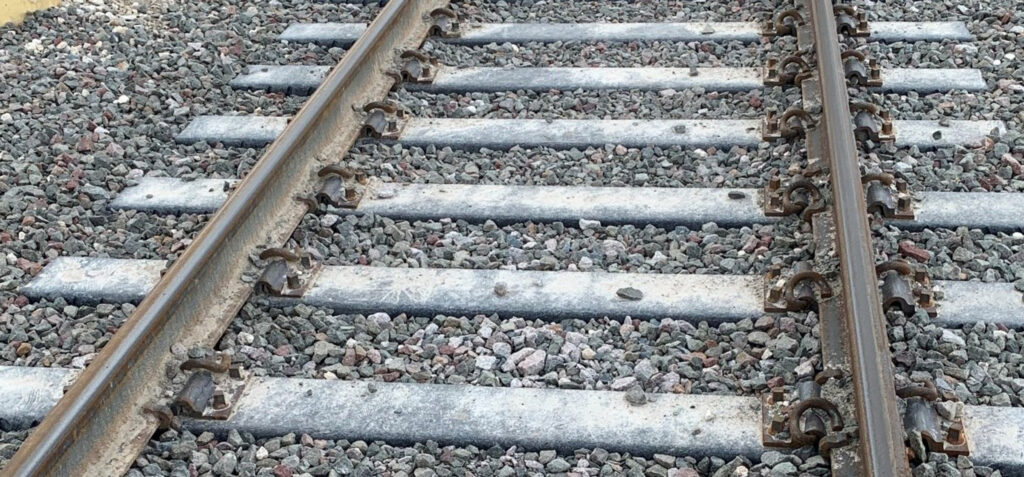

With our Glass Fiber Reinforced Polymer (GFRP) composite railroad ties, Evertrak uses almost 200 pounds of recycled plastic in every tie. All this while delivering the strength and stiffness equivalent to new hardwood railroad ties. When compared to wood ties, these innovative composite rail ties perform better against the fundamental failure modes that plague traditional wood alternatives: rail seat abrasion, spike integrity decline, and—most critically—biological infestation and rot.

With durable recycled materials laying the groundwork, Evertrak’s composite ties are suited for the most demanding environmental conditions and high-tonnage track applications. They’re built to resist moisture and insects while remaining reliable under billions of gross tons of freight for decades.

And the economic value proposition is clear: Evertrak composite ties reduce capital investment and maintenance expenses for railroads. This directly fuels the engine of plastic recycling. Simply put, Evertrak creates powerful economic incentives for recycling by delivering exceptional value to railroads. Evertrak also shows just one way the railroad industry can transform enormous quantities of recycled plastic into innovative technology.

Circular Economy in Action

A few years ago, Evertrak collaborated with a global plastics manufacturer to install Evertrak GFRP composite ties at a Texas polyethylene manufacturing facility. This installation perfectly demonstrates the ideal circular economics of HDPE plastic. Here, virgin HDPE resin produced for consumer and industrial products was recycled from residential curbside and industrial waste streams, then processed into Evertrak GFRP composite ties. These ties will now serve safely and reliably in track for 50 years or more, even in the most severe environmental conditions.

This represents a triple win: for the plastics manufacturer who sees their material reborn in high-performance infrastructure, for Evertrak delivering superior products, and for society collectively benefiting from reduced plastic waste and harmful chemical usage.

Scaling the Circular Economy with High-Performance Rail Ties

Since 2020, when Evertrak converted 3 million pounds of plastic into durable railroad ties, the company has dramatically expanded its impact. As of 2025, Evertrak has now transformed over [info here] million pounds of recycled plastic into sustainable rail infrastructure that also prevents plastic from entering landfills or oceans.

Furthermore, the installation of these composite rail ties saves 250,000 mature hardwood trees from deforestation. Evertrak has over 100,000 installations and zero claims. These sustainable alternatives to wood rail ties have proven their durability and performance in the field.

This represents just the beginning of Evertrak’s commitment to drive the recycling end of a circular economy for plastic across North America and beyond. Producing 1 million Evertrak GFRP composite ties would use 180 million pounds of recycled plastic in long-lasting infrastructure. This reduces capital and maintenance costs for railroads while creating powerful economic incentives for plastic recycling at every level.

North American railroads replace over 20 million wood ties every year, representing approximately 6 million trees. By replacing these ties with the Evertrak 7000 composite ties, we’re driving the economics of plastic recycling. We’re also preventing millions of trees from being harvested to create treated wood ties. This minimizes the amount of harmful creosote leaching into waterways and groundwater.

Closed-Loop Recycling for Maximum Value

The value of recycling reaches its peak when materials continuously cycle through the economy without degradation. Evertrak exemplifies this closed-loop recycling approach. After decades of service, Evertrak ties remain recyclable. Our ties can be melted down and reformed into new ones without compromising performance or requiring additional virgin materials.

This cradle-to-cradle approach maximizes the value of recycled plastic railroad ties while minimizing waste throughout the product lifecycle. By capturing plastic waste and transforming it into critical infrastructure that lasts five times longer than wood alternatives, Evertrak demonstrates how rail tie innovation can drive broader sustainability goals.

Beyond Wood: The Future of Sustainable Rail Infrastructure

Growing freight volumes, aging infrastructure, and increasing environmental pressures—the status quo of wood ties treated with hazardous preservatives no longer meets the rail industry’s modern needs.

Evertrak’s approach to composite rail ties offers a transformative solution that aligns environmental stewardship with economic performance. By utilizing recycled plastic and composite materials in high-performance rail ties, Evertrak enables railroads to simultaneously:

- Reduce lifecycle costs through extended service life.

- Minimize maintenance disruptions with moisture-resistant materials.

- Achieve sustainability objectives by eliminating deforestation and toxic chemicals.

- Support the circular economy through plastic reuse in infrastructure.

- Lead the change in producing ties with environmental benefits.

The circular economy works when economics drive behavior. With more than 20 million ties replaced annually across North America, Evertrak has barely scratched the surface of potential impact. As more railroads recognize the compelling economic and environmental advantages of composite rail ties, the demand for recycled plastic will continue to grow. This emphasis on new technology will create a powerful incentive structure that rewards recycling throughout the supply chain.

At Evertrak, this transformation is called going BEYOND WOOD. We’re not just replacing an outdated material, but reimagining what sustainable rail infrastructure can achieve through composite tie technology and closed-loop recycling. By turning waste into quality, high-value, long-lasting infrastructure, Evertrak demonstrates that the circular economy isn’t just an environmental ideal—it’s sound business that benefits everyone.