The railroad industry is on the cusp of a sustainable revolution, and Evertrak is leading the change!

Traditional wood ties, long plagued by environmental and economic challenges, are giving way to an innovative solution: composite ties made from recycled plastic. This shift is not only transforming railway infrastructure but also driving job creation and economic growth across North America.

Composite Railroad Ties Market Growth Fuels Economic Opportunity

We lead in developing sustainable railway infrastructure through recycled plastic manufacturing. Our flagship product, the Evertrak 7000 tie, proves the potential of recycled plastic railroad ties to deliver superior performance, longevity, and environmental benefits compared to conventional wood ties.

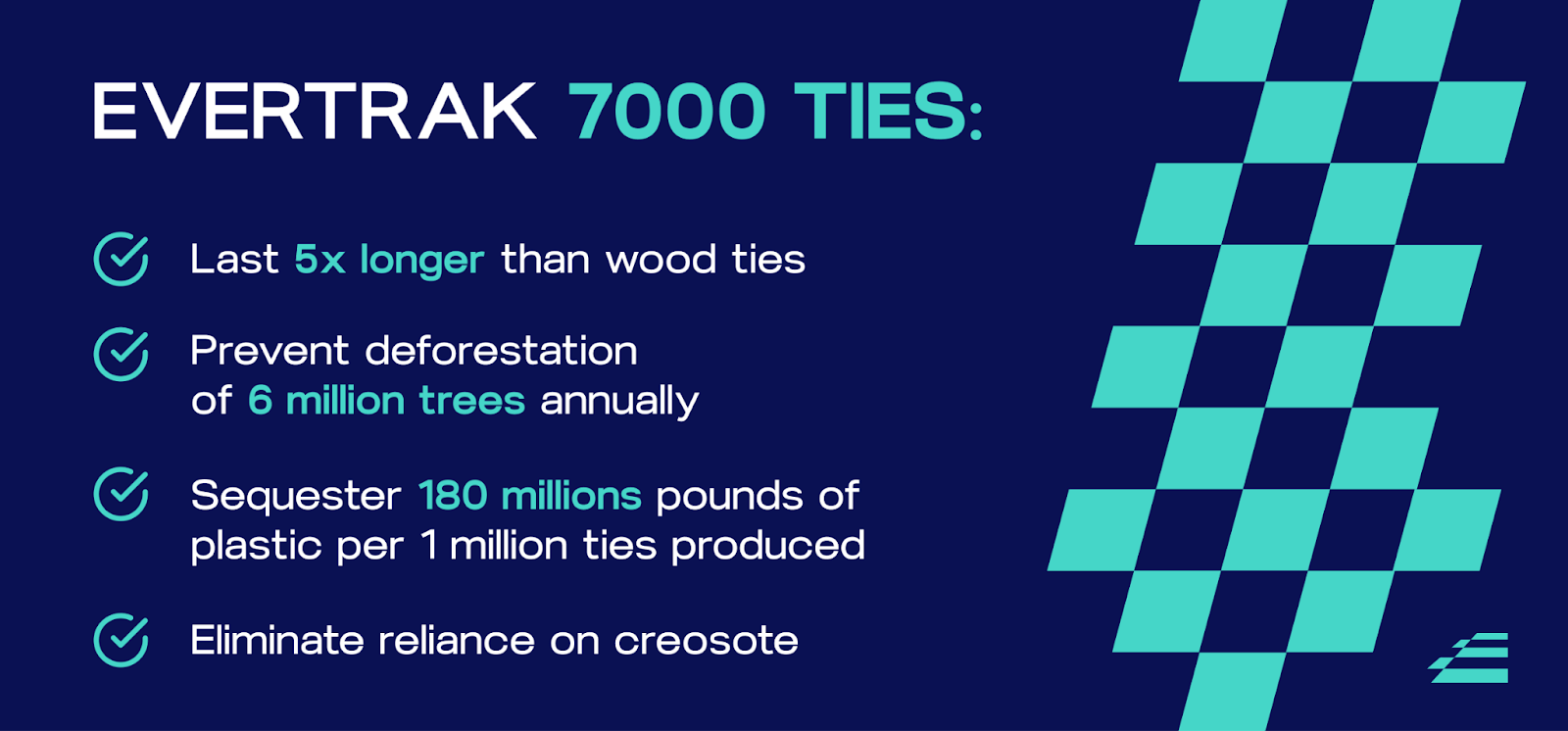

With Evertrak 7000 ties, railroads and their operators benefit from:

- Lifespan lasting up to 5 times longer than wood ties, especially in high-decay zones

- Prevention of deforestation by replacing the 6 million trees cut down annually to replace more than 20 million ties

- Recycling of 180 million pounds of plastic per 1 million ties produced annually, supporting a circular economy

- Elimination of harmful chemicals like creosote used to treat wood ties

This value proposition has spurred rapid adoption by major rail operators and positioned composite ties for explosive market growth. In fact, analysts project the composite railroad ties market will reach $2.4 billion by 2028, growing at a CAGR of 7.2% from 2023 and 2028.

Composite Railroad Tie Manufacturers Drive Job Creation

As demand surges, the economic ripple effects are profound. Recycled plastic tie production creates skilled manufacturing jobs while forging a new industry across the continent.

This job creation potential extends to the broader ecosystem of composite railroad tie manufacturers. As more players enter this burgeoning space, it will spur a wave of hiring and investment in areas like materials science, industrial design, automation, and sustainability—attracting top talent to the rail sector to set us up for future success on all fronts.

Strategic Partnerships Boost Economic Impact

Critical to this growth are partnerships between composite tie makers and major materials suppliers.

Sourcing Materials

Evertrak’s collaboration with Owens Corning, a global leader in engineered materials, exemplifies how these alliances have the potential to amplify economic benefits. When we choose to partner with companies like Owens Corning, we can raise production volumes to increase job growth. Indirectly, it also bolsters employment at upstream suppliers and downstream distributors and installers across the country.

Strategic Investment

We also recently partnered with Sumitomo Corporation of Americas to further advance our commitment toward a more sustainable transportation future. Sumitomo invests in our composite tie technology for sustainable railroad infrastructure across North America.

Through this strategic partnership, we’re better positioned to meet and exceed our sustainable development goals, overcome industry challenges, decrease reliance on wooden ties, implement innovative recycled materials, and expand the improvements we’ve made to composite railroad ties.

These partnerships create jobs and drive technological innovation while securing supply chains and promoting sustainability across industries.

Rail Infrastructure Sustainability Becomes an Economic Engine

Perhaps the most exciting aspect of the composite rail tie revolution is how it aligns environmental stewardship with economic development. Each mile of composite ties represents not just enhanced rail infrastructure sustainability, but also a substantial infusion of jobs, wages, and economic activity into communities.

This synergistic impact is drawing increased attention and investment to green innovation in the rail sector. As major operators like Union Pacific ramp up their commitment to sustainable ties, it signals massive market potential—and an economic boom for the composite materials industry.

Regions hosting tie manufacturing are poised to benefit tremendously as this sustainable industry takes off. Evertrak is proud to be leading the charge from our facilities in St. Louis, where our growth is sparking a green manufacturing renaissance in the heart of Missouri.

The Time for Sustainable Composite Ties is Now

As railroads embrace high-speed trains and renewables globally, now is crucial to overhaul ties and industry trends.

With mounting environmental pressures, aging infrastructure, and surging freight volumes, the rail sector is ripe for disruptive innovation to meet 21st-century demands, and recycled plastic composite ties offer a powerful solution.

Beyond their clear advantages over wooden ties in areas like durability, environmental impact, and lifecycle costs, composite ties represent a uniquely synergistic opportunity. They allow the rail industry to simultaneously solve core business challenges, achieve sustainability objectives, and drive economic development and job creation across North America.

At Evertrak, we’re committed to leading this transformation and maximizing its economic benefits. By forging strategic partnerships, scaling our manufacturing, and constantly innovating, we aim to make composite ties the gold standard for railroads—and a green engine for job growth and prosperity.

The sustainable railroad revolution is here. Embrace composite materials in rail now—building a future that benefits business, planet, and economy alike.

All aboard!