North American railroads are experiencing a fundamental shift in their approach to infrastructure modernization. Rather than relying on wholesale replacement of existing systems, operators realize the value in adopting hybrid railroad tie systems that strategically integrate wood and composite railroad ties based on specific operational requirements.

This measured approach to railroad tie replacement reflects both economic realities and performance data accumulated in recent years. With 140,000 miles of track covering North America’s rail network, railroads spend $25 billion on annual maintenance to upgrade and repair infrastructure for operational use and rail safety. With this budget, roughly 20 million wood ties are replaced each year, showing the future of railroad infrastructure in 2026 and beyond will be defined by strategic material placement, not just uniform solutions.

Railroad Infrastructure Investment Trends Point Toward Hybrid Systems

The railroad industry has moved beyond the traditional debate of wood versus alternatives. The focus is now on optimizing railroad tie lifecycle costs through targeted deployment strategies. For Class 1’s, this means placing composite ties in high-decay zones while maintaining wood ties in areas where they perform adequately.

This trend reflects several converging factors. Wood ties continue to represent 90-93% of North America’s railroad infrastructure, with established supply chains, installation expertise, and proven performance in appropriate conditions. However, specific operational challenges—bridges, tunnels, heavy haul corridors, and high-moisture environments—demand more resilient solutions.

With hybrid tie systems in place, railroads can address their most problematic track sections while preserving capital for other infrastructure investments. Instead of pursuing complete system overhauls, operators can now deploy materials where they provide maximum value.

Advanced Manufacturing Reshapes Tie Placement Strategies

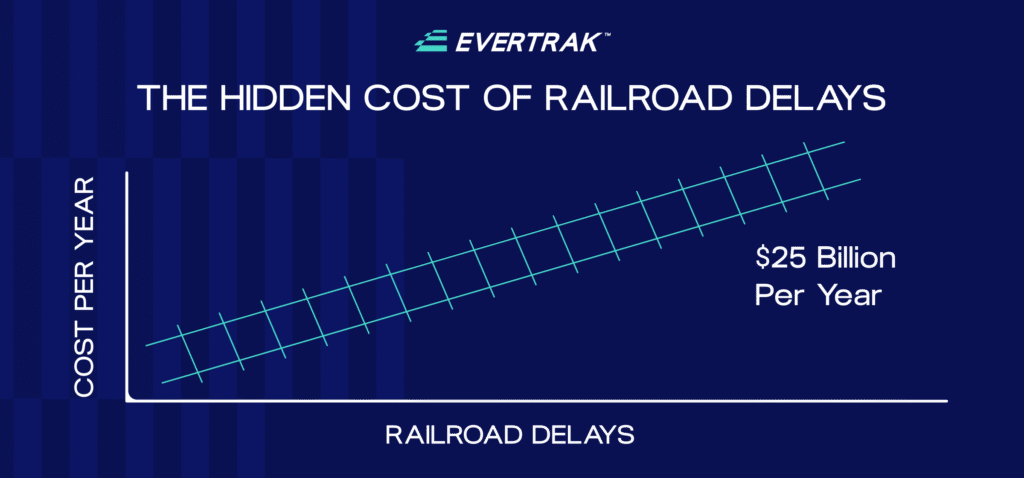

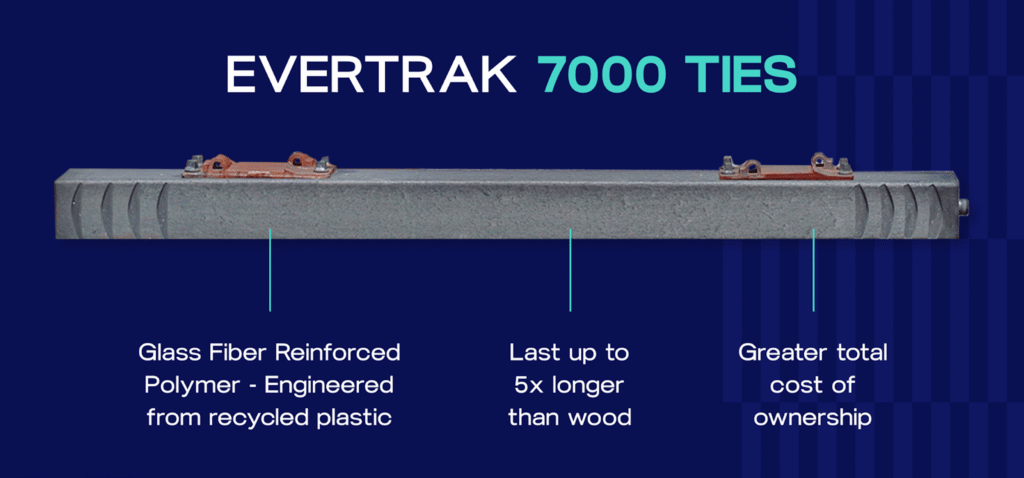

Emerging technologies in railroad tie manufacturing and placement are enabling more precise infrastructure decisions. At Evertrak, we use advanced composite materials that match wood’s installation characteristics while offering superior performance in challenging environments.

Our manufacturing developments include:

- Glass Fiber Reinforced Polymer (GFRP) materials that provide consistent performance across track variations

- Recycled plastic integration that diverts waste from landfills while creating durable infrastructure

- Modular design approaches that facilitate inventory management and logistics

These technological advances support hybrid deployment strategies by ensuring seamless integration with existing railroad infrastructure. Track crews can install wood or composite tie materials using standard procedures, eliminating the operational disruptions traditionally associated with infrastructure changes.

Regulatory Environment Drives Sustainable Track Improvements

Environmental regulations will continue to influence railroad infrastructure decisions in the coming years. From meeting sustainability goals to securing federal funding prioritizing environmental outcomes, sustainable railroad infrastructure has become a business necessity rather than an option.

The regulatory landscape includes responsible hazardous waste management, carbon reporting requirements, and sustainable procurement guidelines. Composite railroad ties address multiple regulatory requirements simultaneously—reducing deforestation pressure, diverting plastic waste, and extending infrastructure lifecycles. These structures encourage hybrid approaches that optimize performance, durability, and sustainability outcomes.

Increase Efficiency and Reduce Costs with Composite Railroad Ties

Economic drivers for railroad infrastructure modernization extend beyond simple purchase price comparisons. Total cost analysis reveals railroad tie lifecycle costs vary dramatically based on placement location and operating conditions.

In high-decay zones, wood ties requiring replacement every 8-12 years at $95 per tie (including labor and equipment) generate lifecycle costs of $475 over a 50-year period. Composite alternatives lasting 50 years in the same conditions eliminate multiple replacement cycles despite higher upfront investment.

Infrastructure cost optimization occurs through:

- Reduced maintenance schedules in problem areas using long-life materials

- Decreased service disruptions from fewer replacement cycles

- Predictable budgeting enabled by extended infrastructure lifecycles

- Resource reallocation from repetitive maintenance to value-adding projects

The economic case strengthens when considering operational impacts. Track downtime for tie replacement in critical corridors can cost operators $232 per hour in delayed freight movements, making lifecycle cost analysis particularly compelling for high-traffic routes.

Smart Infrastructure Integration Transforms Maintenance Approaches

Predictive maintenance technologies are beginning to reshape how railroads manage infrastructure assets. While still emerging, smart railroad infrastructure systems offer the potential to optimize hybrid tie deployment through data-driven decision making.

Advanced inspection technologies leveraging AI can identify specific track sections experiencing accelerated wear, allowing operators to deploy appropriate materials proactively rather than reactively. This capability supports hybrid strategies by ensuring the right material reaches the right location before failure occurs.

Integration opportunities include sensor-equipped ties that monitor track conditions, automated inspection systems that identify replacement candidates, and predictive analytics that forecast infrastructure needs based on traffic patterns and environmental conditions.

North American Railroad Tie Market Outlook

North American freight rail moves 38% of trade-related shipments, 543.5 million tons of goods through U.S. ports, and $29.8 billion in rail revenue. Rail traffic is projected to grow 25% by 2040, leading to an increase in demand for composite materials and hybrid system adoption.

Several factors support this projection:

- Expanding high-decay zones due to climate pattern changes requiring more resilient materials

- Cost optimization and infrastructure investment cycles aligning with hybrid deployment strategies

- Regulatory requirements favoring sustainable material choices

- Performance data validating targeted composite placement

Regional variations will influence adoption patterns. Southeastern markets experiencing severe wood tie deterioration will likely see faster composite integration, while western regions with favorable conditions for wood may maintain traditional approaches in appropriate applications for now.

The market evolution further supports operators pursuing measured infrastructure transitions rather than dramatic system overhauls. This approach aligns capital deployment with operational requirements while building experience with advanced materials.

Evertrak: Composite Tie Value for Hybrid Railroad Infrastructure

Evertrak composite railroad ties deliver exceptional value for operators pursuing hybrid railroad infrastructure strategies. Unlike alternatives requiring specialized installation procedures or enhanced ballast support, Evertrak ties integrate seamlessly with existing wood infrastructure using standard equipment and techniques.

Railroad infrastructure modernization requires solutions that deliver measurable operational improvements alongside material performance. Evertrak ties support hybrid strategies by transforming high-risk zones from operational liabilities into reliable assets, allowing railroads to focus resources on strategic growth instead of perpetual maintenance cycles.

The business case strengthens when considering capital spent on repeated emergency repairs generates no return—it merely maintains existing capacity. Strategic composite placement in failure-prone zones converts this maintenance burden into infrastructure that supports consistent, reliable service for decades.

Building Tomorrow’s Railroad Infrastructure Today

The path forward for North American railroad infrastructure balances respect for proven systems with strategic adoption of advanced materials. Hybrid railroad tie systems enable this balance by deploying materials where they perform best while preserving functional infrastructure elsewhere. Operators who embrace hybrid approaches position themselves to address changing operational conditions without massive capital outlays or operational disruptions.

The railroad industry has always solved complex challenges through practical solutions. Hybrid infrastructure systems continue this tradition, offering measured pathways to more sustainable, cost-effective railroad operations that serve communities and commerce for generations ahead.For operators ready to explore hybrid railroad infrastructure strategies, the key lies in identifying high-value deployment opportunities where advanced materials can deliver maximum benefit. Strategic placement of composite railroad ties within existing wood infrastructure represents smart resource allocation and the foundation of resilient railroad networks built for 2026 and beyond. Reach out to kickstart your rail tie transformation.