Railroad efficiency is measured in minutes. A single hour of mainline delay can have a serious impact on the transit of goods across the supply chain and can cascade into days of scheduling complications, missed connections, and deteriorating customer relationships.

While the industry meticulously tracks on-time performance, the connection between tie failure and service disruptions often remains underexamined—despite track infrastructure ranking among the leading causes of unplanned outages not just in North America but globally.

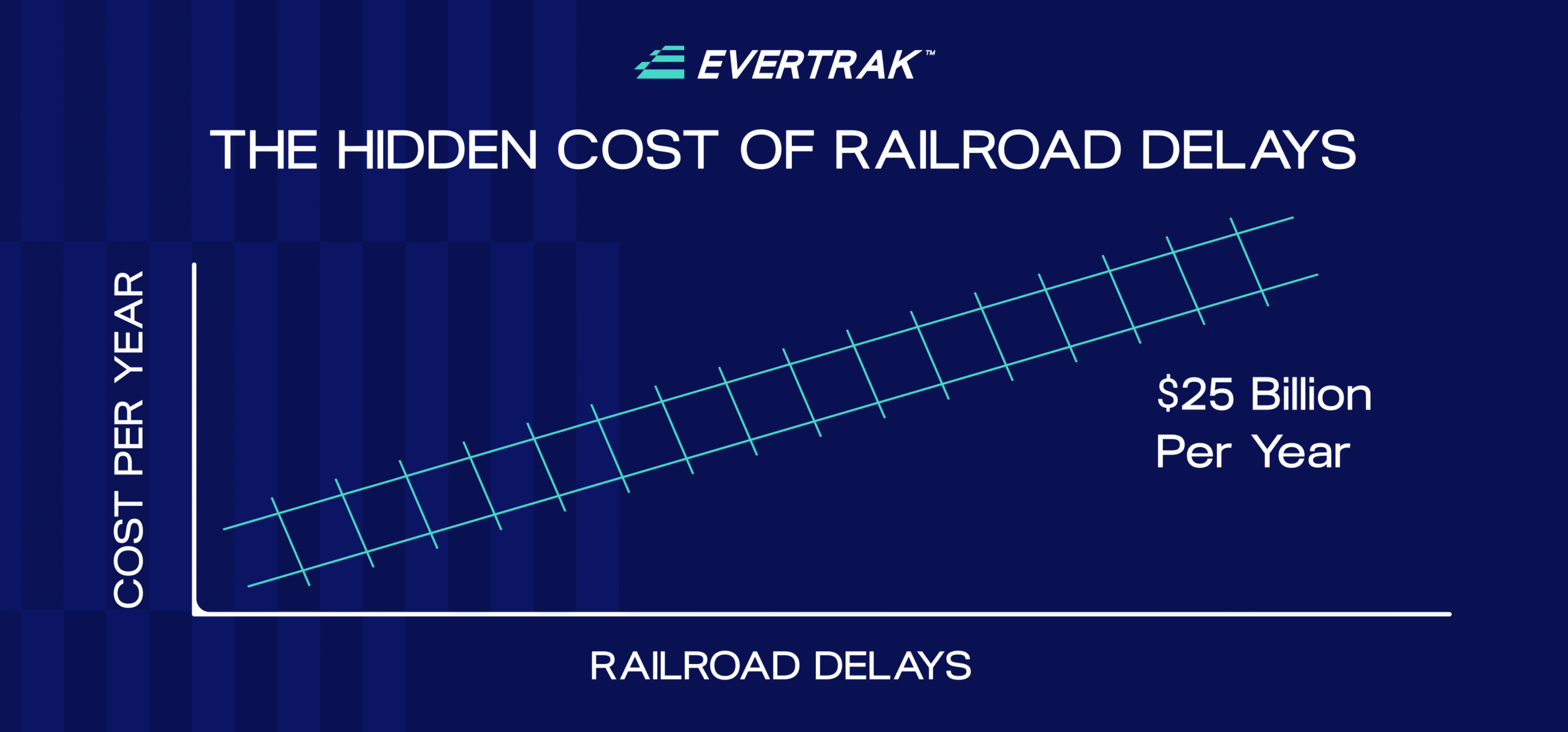

Railroad owners invest 19% of their revenue to maintain and add capacity to their systems, spending roughly $25 billion each year. So, when railroad ties fail unexpectedly, the costs multiply far beyond the price of replacement materials. Strategic deployment of composite ties in failure-prone zones offers railroads a measurable route to reducing these hidden expenses through improved infrastructure reliability.

Significant Supply Chain Impact: Quantifying the True Cost of Railroad Delays

The financial impact of railroad delays extends well beyond the immediate operational disruption. Direct costs accumulate quickly, including:

- Emergency crew deployment

- Equipment repositioning

- Expedited materials

- Overtime labor

And indirect costs often overshadow these immediate expenses:

- Network congestion: One stopped train affects every train behind it

- Crew timeouts: Federal hours-of-service regulations mean delayed crews may need replacement workers

- Customer penalties: Many shipping contracts include delay penalties

- Modal shift risk: Repeated train delays push some shippers toward trucking alternatives

- Storage and demurrage: Delayed shipments incur additional terminal fees

- Safety issues: Construction and work around trains is never without risk

For Class I railroads like Union Pacific moving 40 to 70 trains per day—keeping in mind that 10% of Union Pacific’s trains are over 2.5 miles long—a single track failure can impact dozens of freight trains within hours. When tie failure forces speed restrictions in a certain location rather than complete closure, the efficiency losses compound over weeks or months as every train loses time through the affected section.

The reputational costs prove hardest to quantify but matter significantly. Precision Scheduled Railroading (PSR) has raised customer expectations for reliability, including the expected schedule, carrier, transit routes, trips, and destination. When supply chain infrastructure failures on affected lines undermine construction and maintenance schedule adherence, railroads risk losing high-value contracts to competitors who leverage alternate routes. Customers who don’t have to use trains to transport their materials may even seek out alternative transportation modes.

Rail Infrastructure as a Leading Cause of Service Interruptions

Federal Railroad Administration data consistently shows track defects among the primary causes of train accidents and service disruptions. In fact, track infrastructure failures are responsible for as much as 52% of derailments. While dramatic derailments capture headlines, the steady drain of minor infrastructure failures in this crucial supply chain costs the industry far more annually.

Tie failure contributes to service interruptions through multiple mechanisms:

Immediate failures requiring emergency response:

- Broken ties under heavy loads

- Gauge widening from deteriorated ties

- Rail rollover from inadequate tie support

Progressive failures requiring train speed restrictions:

- Clusters of marginal ties requiring slow orders

- Seasonal failures during wet periods

- Accelerated deterioration in problem zones

Cascading effects from deferred rail maintenance:

- Ballast deterioration around failed ties

- Increased rail stress from poor tie conditions

- Accelerated wear on adjacent infrastructure

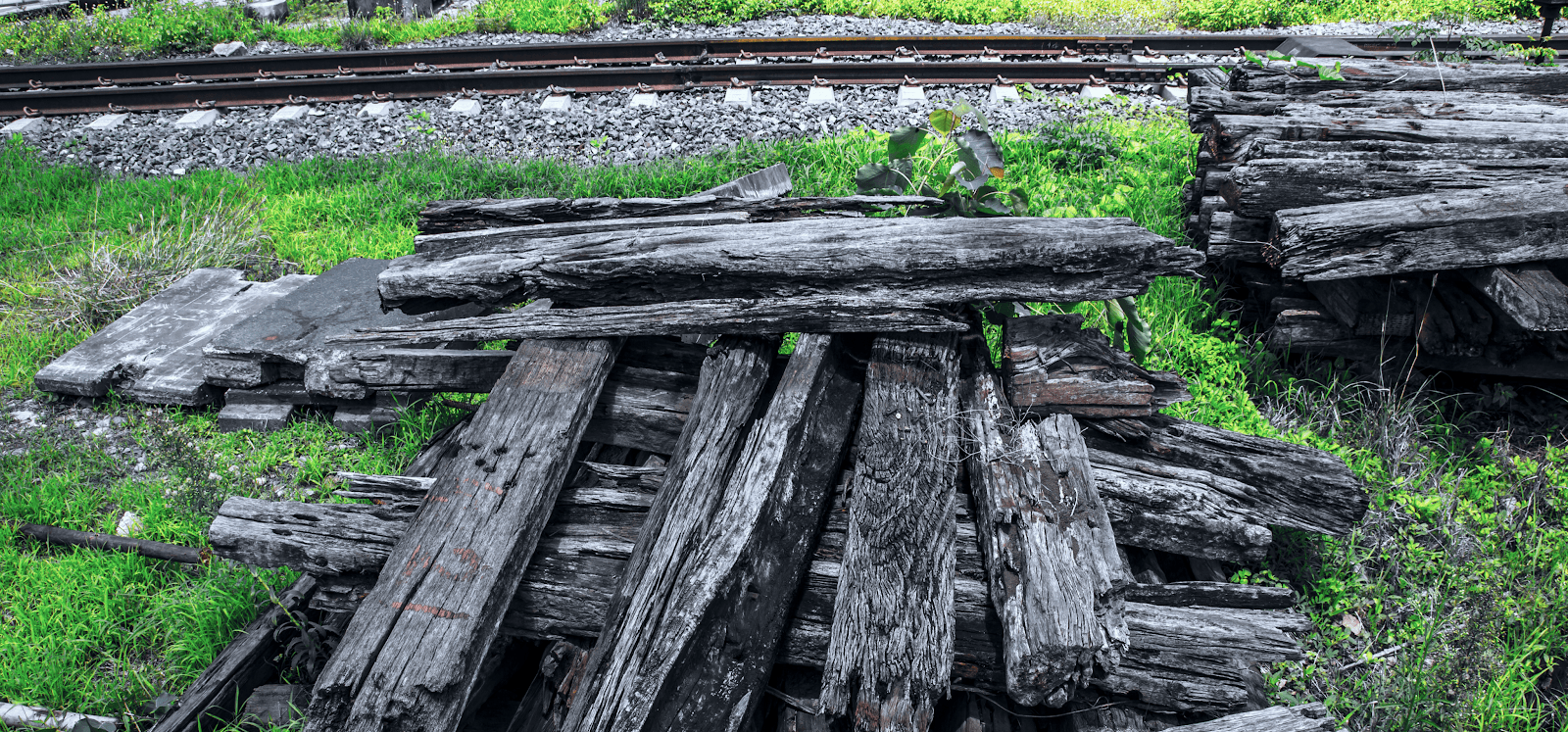

The unpredictability of wood tie failure particularly challenges operational planning. While railroads budget for regular tie replacement, emergency failures occur outside planned service windows, maximizing disruption and cost.

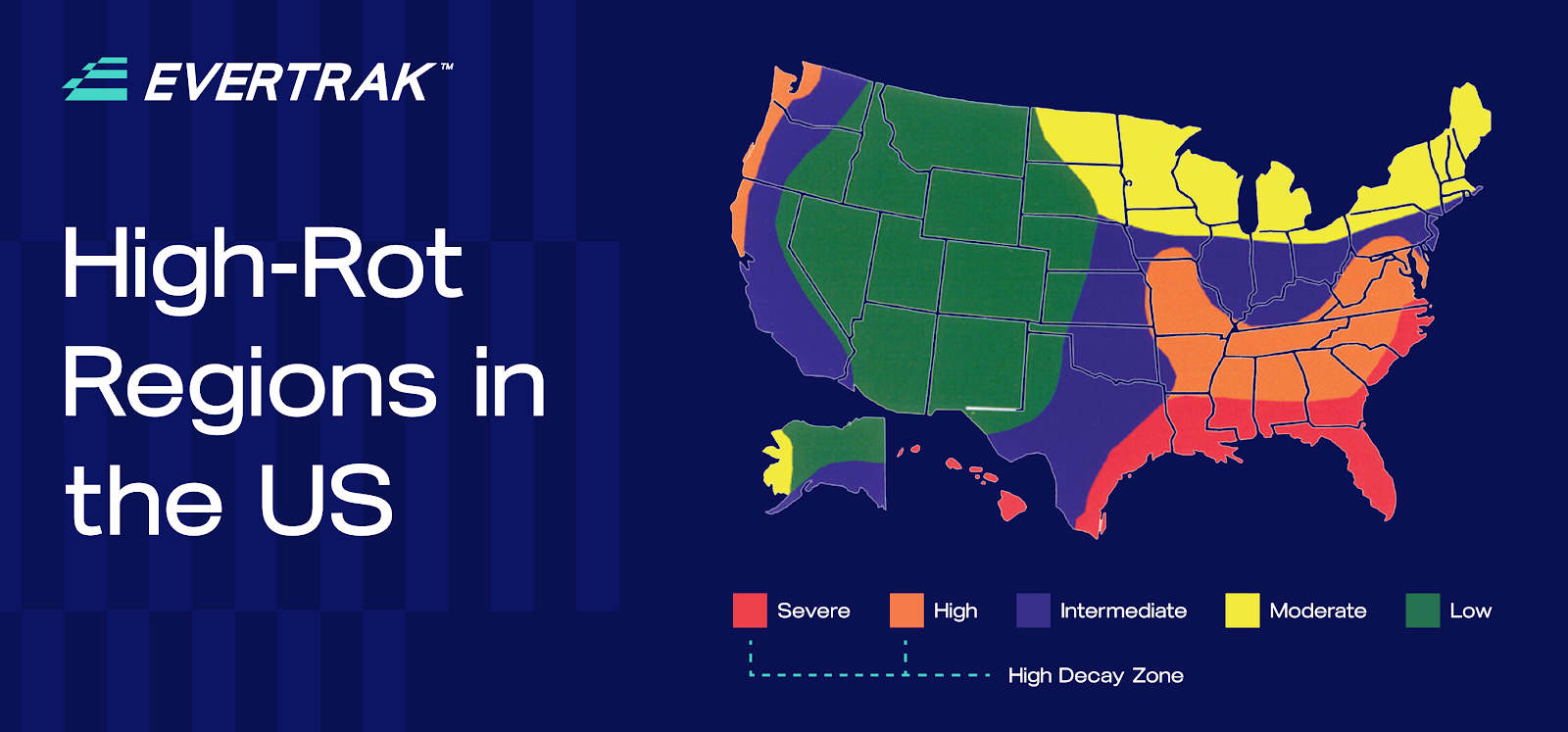

Supply Chain Support: Identifying High-Risk Zones for Tie Failure

Given that all trains aren’t the same length, don’t travel at the same speed, travel through different environments, and carry loads of all different weights and sizes, not all tracks face equal risk. Specific conditions and certain routes accelerate tie deterioration and increase failure probability:

Environmental factors:

- High-moisture areas where wood decay accelerates

- Extreme temperature zones causing expansion/contraction stress

- Areas with heavy insect activity

- Locations with poor drainage

Operational stress points:

- Curves where lateral forces stress ties

- Heavy grades with increased train load forces

- Bridge approaches with transition stresses

- Yard throats with frequent switching movements

Historical problem areas:

- Sections with repeated emergency repairs

- Zones requiring frequent train speed restrictions

- Areas with shortened replacement cycles

- Locations with soil stability issues

In the Southeastern U.S., 10–12% of ties (around 20 million) require annual replacement, compared to 3–3.5% nationwide. These high-decay zones represent concentrated risk for service disruptions.

Modern predictive maintenance systems can identify these risk zones through:

- Tie condition assessment data

- Historical failure patterns

- Environmental monitoring

- Load and traffic analysis

Composite Ties as Preventive Supply Chain Infrastructure Investment

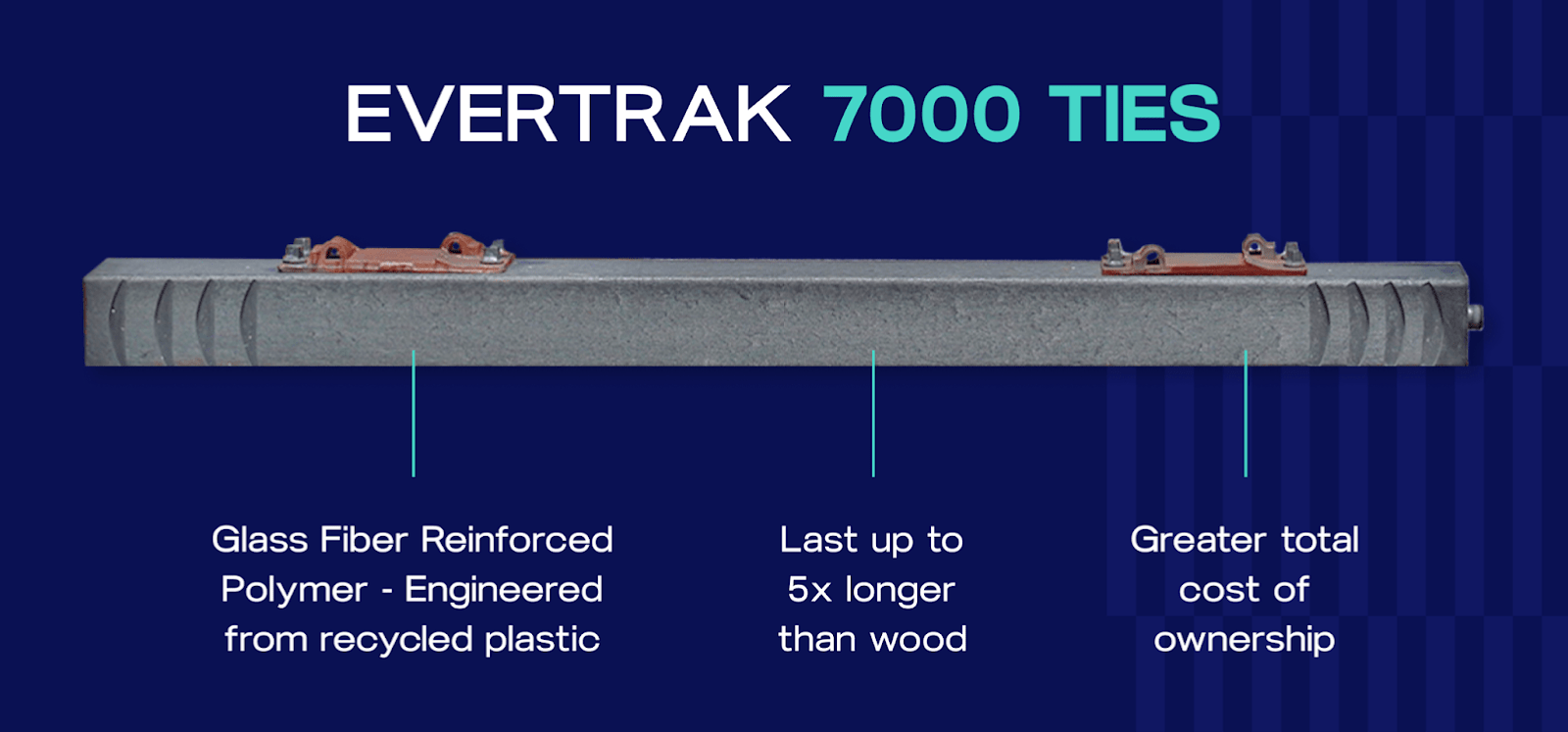

Strategic placement of Evertrak composite ties in high-risk zones transforms reactive maintenance into proactive reliability improvement. With validated lifespans of up to 50 years even in challenging environments, composite ties effectively eliminate failure risk in treated sections.

The preventive value extends beyond individual tie performance:

Consistent track geometry: Composite ties maintain dimensional stability, preventing the gradual degradation that leads to speed restrictions

Predictable maintenance windows: With 50-year lifespans, composite sections can be scheduled for inspection rather than emergency repair

Weather resilience: Immunity to moisture, insects, and decay means weather events don’t trigger failure cascades

Load consistency: Uniform strength properties eliminate weak points that could trigger emergency repairs

To date, Evertrak is proud to report zero claims across over 100,000 installations (including installations with Union Pacific)—demonstrating the reliability that prevents unexpected failures.

The interoperability of Evertrak ties with existing wood infrastructure means railroads can target specific risk zones without disrupting broader operations. Unlike concrete ties that require engineering studies and modified procedures, composite ties are installed using standard equipment and methods, enabling rapid risk mitigation.

ROI Calculations: Delay Prevention vs. Composite Tie Investment

The return on investment for strategic composite tie placement becomes clear when factoring in delay prevention:

Traditional wood tie scenario (high-risk zone, average per mile):

- 94 failures per mile, per year

- 3-hour delays per emergency repair

- $232 per train-hour (conservative estimate for Class I railroad delay costs)

- $65,733 annual delay cost (94 repairs x 3 hours x $232)

- $657,444 10-year total with replacements and delays

Evertrak ties provide significant cost savings over time, despite the slightly higher initial investment (as compared to wood ties). When analyzing high-rot zones over 30 years, the total cost of ownership for one track mile of wood ties can reach well over $1M, compared to $676K for Evertrak ties.

Ultimately, Evertrak delivers 2x the total cost of ownership advantage, including minimal to no emergency repairs and associated costs.

Beyond quantifiable delay prevention, composite ties deliver additional value:

- Reduced inspection frequency

- Eliminated chemical treatment costs

- Decreased rail wear from stable tie conditions

The investment case strengthens when considering opportunity costs. Capital and labor spent on repeated emergency repairs could be redirected toward network expansion, technology upgrades, or service improvements that generate revenue rather than simply maintaining the status quo.

Building Reliability Through Strategic Investment

The hidden costs of railroad delays make a compelling case for preventive infrastructure investment. Every emergency tie repair, speed restriction, and service disruption erodes both profitability and customer confidence. Strategic placement of composite ties in high-risk zones offers measurable returns through:

- Eliminated emergency repairs in treated sections

- Improved on-time performance metrics

- Reduced maintenance crew scheduling pressure

- Enhanced customer satisfaction and retention

- More predictable operational planning

At full production of one million Evertrak ties annually, the industry could address its highest-risk infrastructure systematically, transforming reactive maintenance into proactive reliability.

Railroad success depends on consistent, reliable service. By investing in composite ties for failure-prone zones, operators can reduce the hidden costs that drain resources and undermine performance. The question isn’t whether railroads can afford to invest in composite ties—it’s whether they can afford not to.The path to improved reliability starts with identifying your highest-risk zones. Connect with our experts to discuss how strategic composite tie placement can reduce delays and improve your network’s performance.