With over 140,000 miles of track and approximately 450 million railroad ties in service on North American railroads, wood comprises 90-93% of our rail infrastructure. This massive installed base represents centuries of investment, institutional knowledge, and operational familiarity that won’t—and shouldn’t—disappear overnight.

But wood ties face increasing challenges. In high-decay zones across the Southeast and increasingly in other regions, ties that should last 20–25 years are failing in 8–12 years. Some are rotting from the inside out in less than five years. The traditional response has been wholesale replacement with more wood, creating an expensive cycle of decay and renewal that costs Class 1’s like Union Pacific approximately $1.9 billion annually.

There’s a smarter approach: strategic integration of composite railroad ties within existing wood infrastructure.

The Strategic Placement Approach: Maximizing Value Where It Matters Most

Not every mile of track faces the same challenges. While wood ties perform adequately in dry climates and low-stress areas, specific zones demand more resilient solutions. These problem areas—bridges, tunnels, curves, grade crossings, heavy haul track, and regions with high moisture or insect activity—accelerate wood tie failure and drive disproportionate maintenance costs.

Evertrak Composite Railroad Ties Are Engineered Specifically for Seamless Integration with Wood Infrastructure

Unlike concrete ties that require intensive engineering assessments, enhanced ballast support, and specialized mixing patterns, Evertrak’s composite ties match wood’s:

- Weight

- Durability

- Flexibility

- Fastening requirements

Track crews can install Evertrak railroad ties using existing equipment and procedures, placing them precisely where wood struggles most. To learn more, download our performance technical data sheet.

This targeted approach transforms tie replacement from a wholesale infrastructure overhaul into a precision maintenance strategy. Railroads can address their most problematic sections of track while maintaining functional wood ties elsewhere, extending the overall life of their rail network without disrupting operations or requiring massive capital outlays.

Railroad Tie Cost-Benefit Analysis: The Cost-Effective Economics of Hybrid Systems

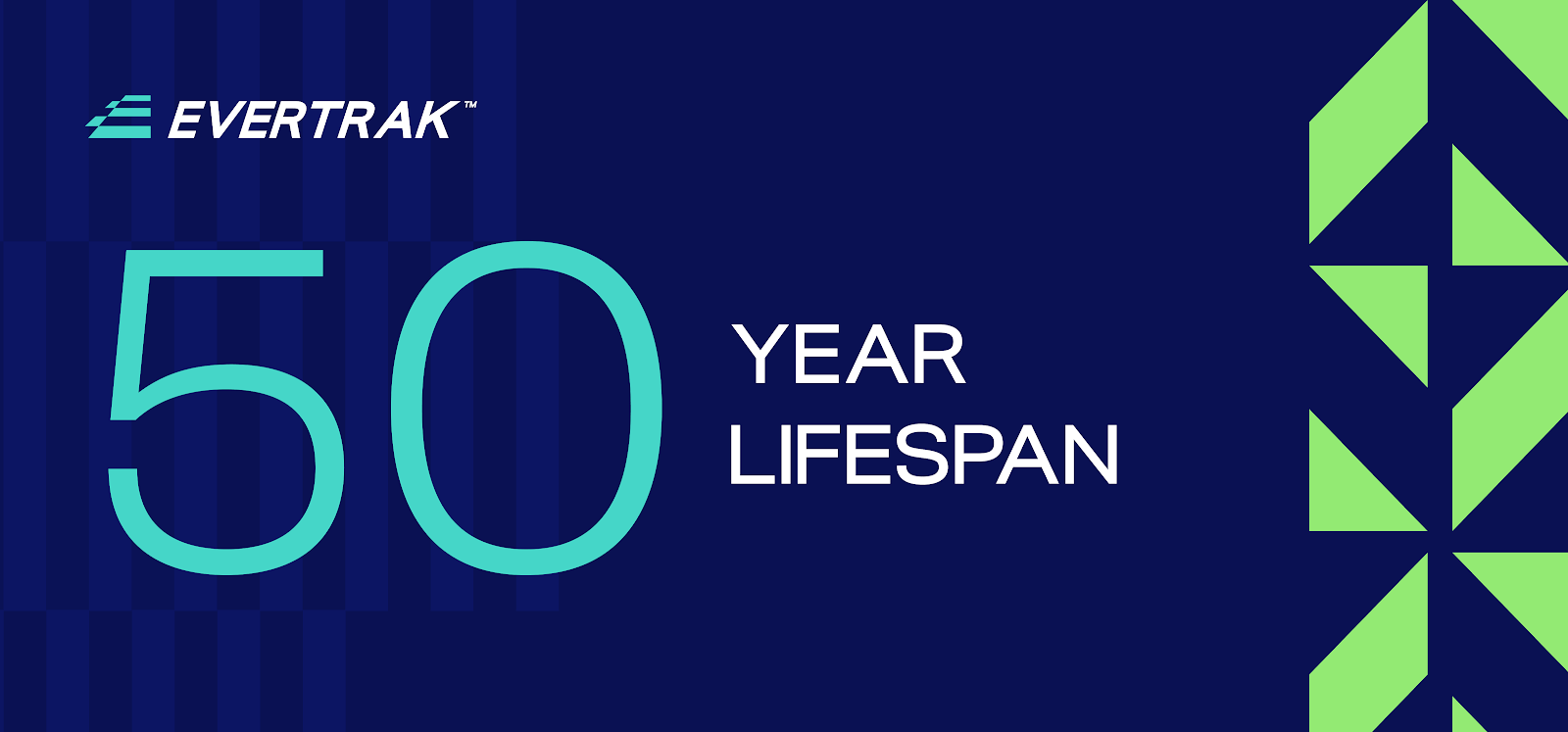

The financial case for hybrid wood-composite systems becomes clear when examining total lifecycle costs. Consider a typical high-decay zone where treated wood ties require replacement roughly every 10 years at $95 per tie (including labor and equipment). Over 50 years, that single tie position costs $475. As mentioned earlier, with 20 million ties replaced annually, railroads spend nearly $2 billion on tie replacements each year.

However, an Evertrak composite railroad tie, lasting 50 years in the same environment, eliminates four replacement cycles despite slightly higher upfront costs. And because our ties are made from recycled plastic, when they need to be replaced, they can be melted down and transformed into new ties.

But the savings with composite railroad ties extend beyond direct replacement costs:

- Reduced track downtime: Fewer replacement cycles mean less service disruption

- Lower maintenance frequency: Composite ties in problem areas reduce overall maintenance schedules

- Predictable budgeting: Extended lifespans enable more accurate long-term planning

- Operational efficiency: Crews can focus on other maintenance priorities rather than repeatedly addressing the same problem zones

The hybrid approach also preserves capital for other investments. Rather than spending billions on complete track replacement, railroads can allocate resources strategically, addressing immediate problems while planning measured transitions over time.

Real-World Implementation of Composite Railroad Ties Alongside Wood Ties

Union Pacific’s adoption of Evertrak ties demonstrates the practical benefits of targeted composite placement. As reported in Railway Age, the Class 1 railroad has installed Evertrak ties in areas where wood tie lifespan averages just 8–15 years due to heat, humidity, and subgrade conditions, compared to 25 years in other parts of their network.

In late 2023, Union Pacific deployed Evertrak ties around Little Rock, AR; St. Louis, MO; Fort Worth, TX; and Reno, NV, as well as on several bridges. These installations target specific environmental and operational challenges rather than pursuing wholesale replacement.

Tim Noonan, Evertrak’s founder and CEO, shared insights with Railway Age from conversations with three Class 1 chief engineers who witnessed ties “rotting from the inside out, failing in less than five years in the Southeastern U.S.” This accelerated failure rate in high-decay zones—where around 12% of ties require annual replacement versus 3.5% nationwide—makes targeted composite placement particularly valuable.

Sumitomo Corporation’s strategic investment in Evertrak earlier this year validates this approach. Sumitomo, already supplying rail, tie plates, wheels, and axles to the industry, recognized the synergies between Evertrak’s composite ties and existing railroad infrastructure, supporting enhancement rather than replacement of current systems.

Composite Railroad Tie Implementation Timeline and Best Practices

Successfully integrating composite railroad ties into wood infrastructure when traditional ties need to be replaced isn’t complicated, but it still requires thoughtful planning:

Phase 1: Assessment and Prioritization

- Map high-failure zones using maintenance records

- Identify areas with shortest replacement cycles

- Calculate current annual costs for problem sections

Phase 2: Pilot Installation

- Begin with highest-ROI locations (such as curves and high-rot regions)

- Like Union Pacific, install composite ties during regularly scheduled maintenance windows

- Train crews on installation best practices (such as pre-drilling spike holes to ensure optimal placement)

Phase 3: Monitoring and Expansion

- Track performance metrics in hybrid sections

- Document maintenance savings and operational improvements

- Gradually expand composite placement based on results

Phase 4: Long-term Integration

- Develop replacement schedules that optimize wood/composite mix

- Establish inventory management for both tie types

- Create maintenance protocols for hybrid track sections

Long-Term Maintenance Projections for Composite Railroad Ties

The maintenance advantages of hybrid systems compound over time. By eliminating frequent replacements in problem zones, railroads can reallocate maintenance resources more effectively.

Consider a 100-mile section with 20 miles of high-decay zones. Traditional all-wood maintenance might require:

- Annual inspection and treatment of all ties

- Frequent replacement of high-decay zone ties annually

- Repeated disruption to service for emergency repairs

With strategic Evertrak composite tie placement in those 20 problem miles:

- 50-year lifespan eliminates multiple replacement cycles

- Reduced inspection frequency for composite railroad tie sections

- More predictable maintenance scheduling

- Freed resources for other track improvements

Building the Future on Today’s Foundation

The path forward for North American railroads is collaborative, one that uses materials where they perform best. Evertrak composite ties don’t compete with functional wood infrastructure, and where they’ve replaced wood ties, they continue to deliver outstanding performance. Instead, Evertrak complements traditional railroad ties by solving specific problems that wood cannot address economically.

Evertrak is dedicated to respecting the industry’s history while addressing its future needs. And with Evertrak’s Glass Fiber Reinforced Polymer (GFRP), durable, recycled plastic solution, railroad companies can maintain their existing wood tie inventory, equipment, and expertise while strategically deploying quality composite ties to extend track life, reduce maintenance costs, and improve network reliability.

As weather patterns shift and decay zones expand northward, the flexibility to integrate durable composite ties within wood infrastructure becomes increasingly valuable. Railroads that adopt this hybrid strategy position themselves to manage changing conditions without massive infrastructure overhauls.

The railroad industry has always been built on practical solutions to complex challenges. By working with existing infrastructure rather than against it, Evertrak composite ties offer railroads a measured, economical path to more sustainable operations. One strategic placement at a time, one mile at a time, we’re helping build stronger, more resilient rail networks that serve communities and commerce for generations to come.For more information about implementing Evertrak composite ties in your high-challenge zones, contact our team to discuss a targeted assessment of your track infrastructure.